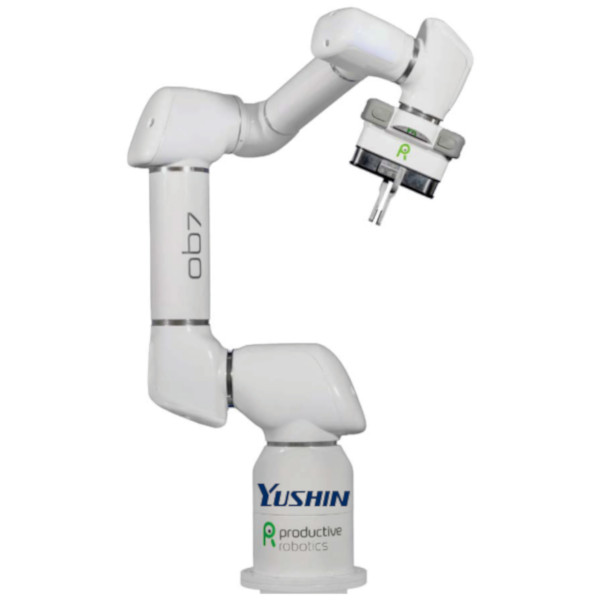

Collaborative Automation is now within your Grasp

OB7 was designed to deliver unmatched automation productivity, accuracy, and safety. And, you can do it all simply without complicated software programming and coding.

OB7 Learns with no programming

If you can do the job, you can show OB7 how to do the job. Learning without programming means that anyone can teach OB7 to do hundreds of complex automation jobs simply and quickly.

Next generation collaborative & safe

OB7 is the next generation of collaborative robots, with new functionality and systems designed to reduce costs and safely open new productivity horizons. OB7 is fully compliant with ISO 10218-1, work safely guidelines and requirements. When equipped with safety sensors, OB7 can safely work at high speeds when people aren’t present then slow to safe speeds when people are nearby.

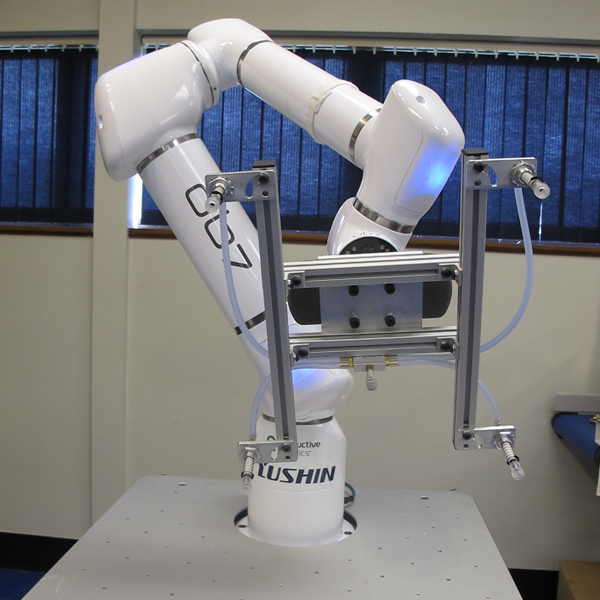

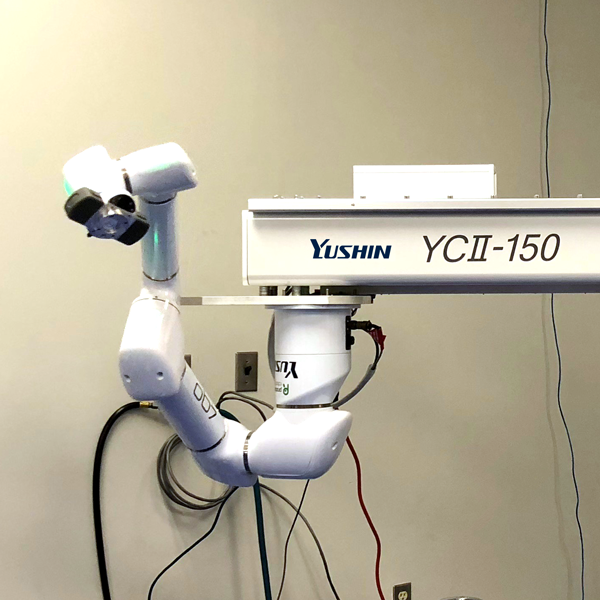

Automate all areas of manufacturing

- Machine Tending and Batch Production

- Packaging and Palletizing

- Loading, Unloading and Part Removal

- Gluing, Painting and Welding

- Polishing, Cutting, Deburring and Grinding

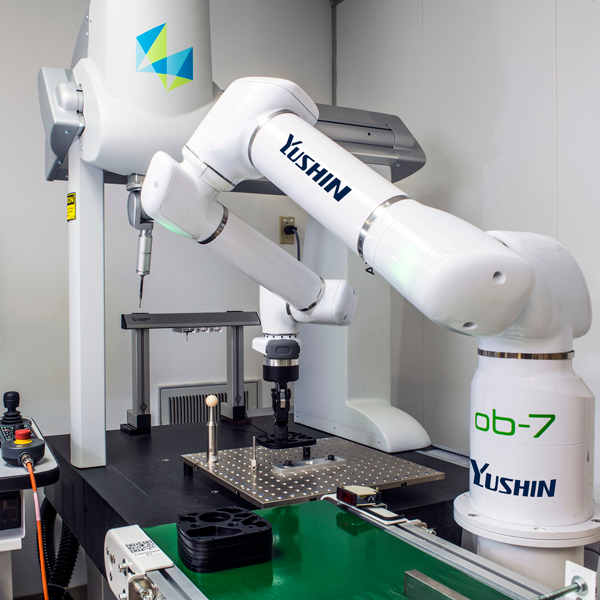

- QC Measuring, Testing, and Inspection

OB7 Seven Axis Work Envelope Advantage

A 7th Axis, sometimes called “7 Degrees of Freedom”, just means ultimate flexibility. Like a human arm, 7 joints give OB7 the flexibility and dexterity to reach around objects or obstacles in the work area, which is impossible with only 6 axes.

Beyond the capability of a human arm, each of OB7’s joints can rotate 360 degrees both directions. 7 axes, each with +/- 360 degrees of rotation, allows OB7 to work in more confined work spaces and reach areas that a 6 axis robot can’t reach.

The increased flexibility of 7 axes enables more ergonomic work efficient orientations to streamline the job automation.

Reviews

There are no reviews yet.