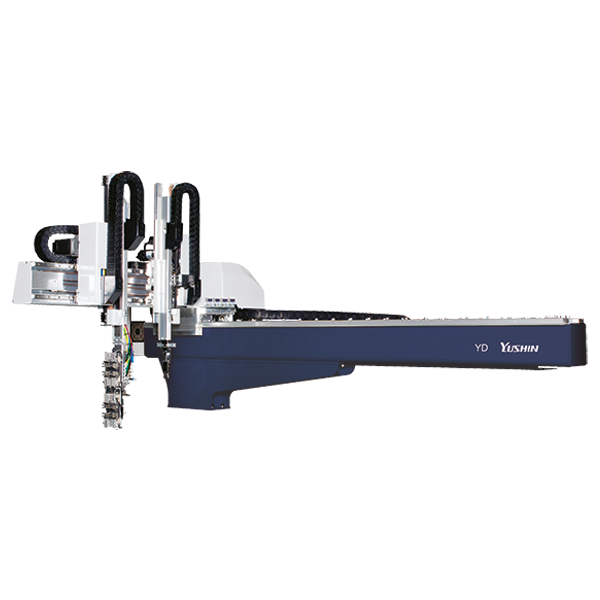

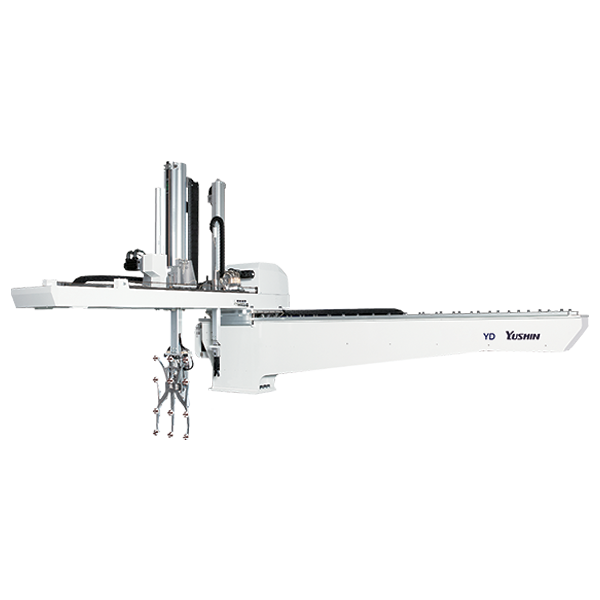

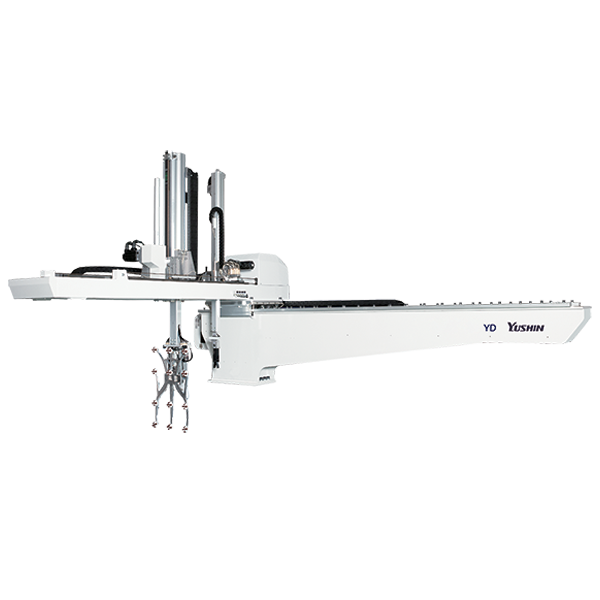

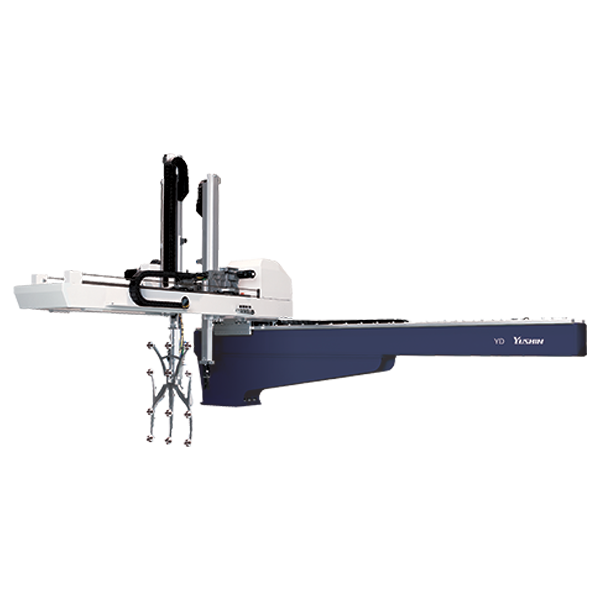

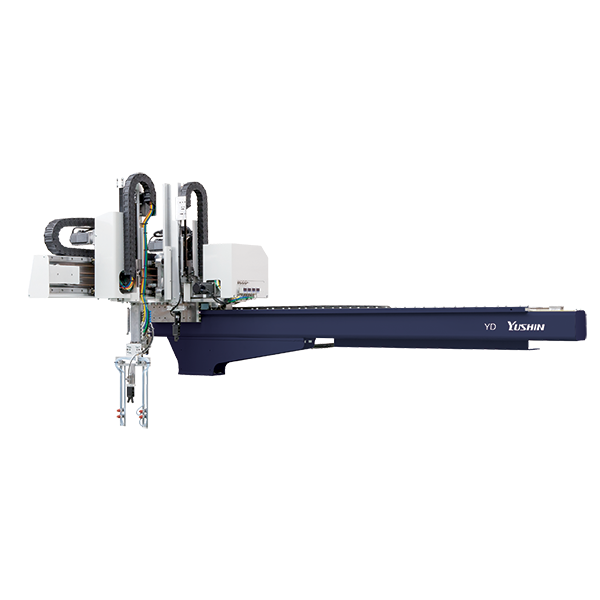

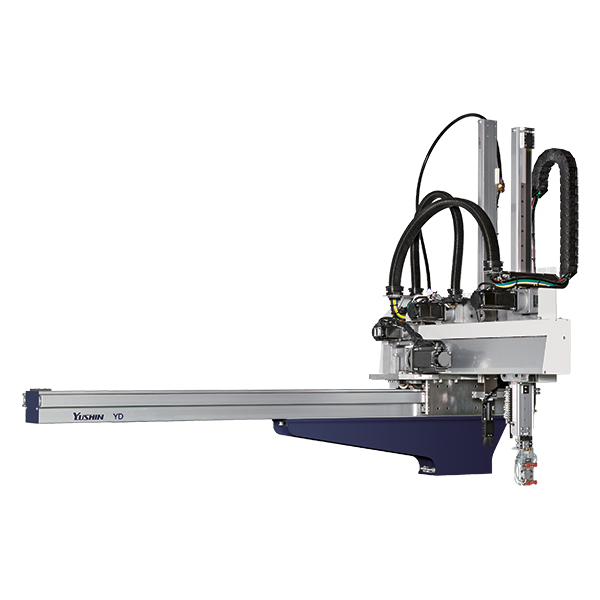

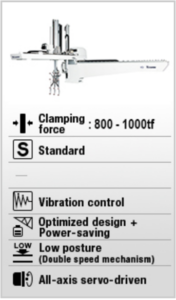

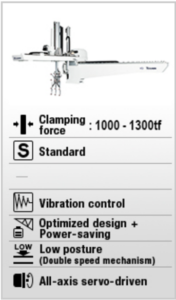

YD/YDII series: Standard Take-out Robots

Enhanced design for higher productivity, less downtime, and lighter environment footprint.

Productivity Enhancements

46% Better Flexural Rigidity Than Previous Model, and 13% Reduction in Vibration Amplitude

YD series robots utilize parts constructed of CFRPv3(*) and gained 46% improvement in flexural rigidity as well as a 13% reduction in single-arm vibration amplitude, compared to previous models. Stable operation with less vibration helps raise productivity by preventing scratches or damage to products during take-out, and reducing the occurrence of take-out failures.

(*): Third generation Carbon Fiber Reinforced Polymer that outperforms the CFRP used in previous YC series robots.

Teaching Enhancements

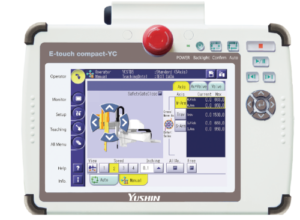

- Cycle-Up function (PAT.P) – This feature displays required times per robot operation in a step-by-step list. This aid helps operators identify and target areas of the sequence to achieve shorter overall cycle times and raise productivity.

- Manual Torque Monitor – Displays a torque gauge for each axis during robot teaching, to show operator how much load the robot bears in motion. This aid allows operators to observe slight fluctuations in torque and fine-tune difficult-to-teach programs, like for insert molding.

- All-axis Manual Operation screen – Operators can see and control all axes on just a single screen, enhancing operability.

- Highly Operable E-touch Compact3 – The E-touch compact3 takes the easy operability of the previous YC series controller and adds several assist features to become even easier to use.

Downtime-Preventing Enhancements

The robot automatically monitors vacuum pressure during take-out operations to identify patterns and assist in finding causes of take-out failures. Each vacuum circuit is monitored individually to more quickly find abnormal circuits. The robot records the frequency of take-out failures, so operators can more easily recognize when maintenance is needed, or more easily find causes after trouble occurs. Diagnosis results are displayed on the Take-Out Failure Details screen, where operators can see vacuum pressure values and bad take-out patterns that have occurred.

Reviews

There are no reviews yet.