NEW Yushin Product!

Powerful Selection of Standard Features

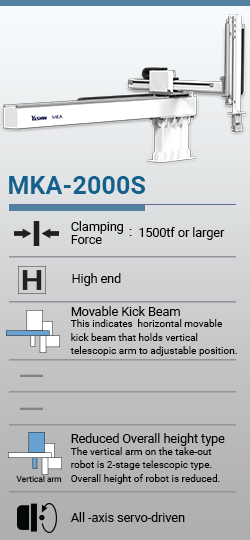

Powerfully automate extraction of large, heavy molded parts such as automobile parts, housing appliances, and parts for industrial equipment. The MKA-2000S can handle payloads of up to 50 kg (including the end-of-arm tool) and stably take out ultra-large molded articles.

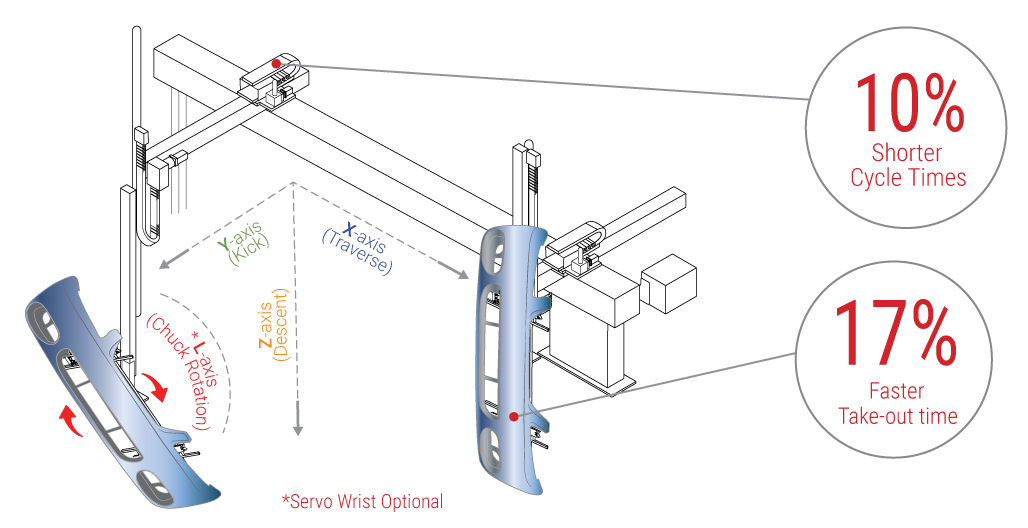

The MKA-2000S robot features a 3-axis, Cartesian style traverse robot with a movable kick beam and a 2-stage telescopic vertical arm. The long rigid, steel traverse beam is adjustable up to 5000mm, with a horizontal reach of 1800mm and a telescopic Arm with vertical strokes up to 3000mm. The MKA-2000S robot works on machines of 1500 molding tons or larger.

In addition to the 3-axes motion, a servo AC or BC wrist unit can be added, allowing for additional articulatory movements for complex EOAT motion. Two types of servo-powered wrist units are available as an option, enabling precision control and motion comparable to an articulated 6-axis robot. The MKA robot can lift up to 50kg.

The MKA-2000S has been tested and proven to exceed its previous larger counterparts like the RBII-2500S with shorter take-out times by 17%. The low profile design of the MKA allows for work envelopes with lower overhead clearance. It’s superior vibration damping during movement and stops helps ensure stable and shorter cycle times by 10%, compared to previous larger models.

Reviews

There are no reviews yet.